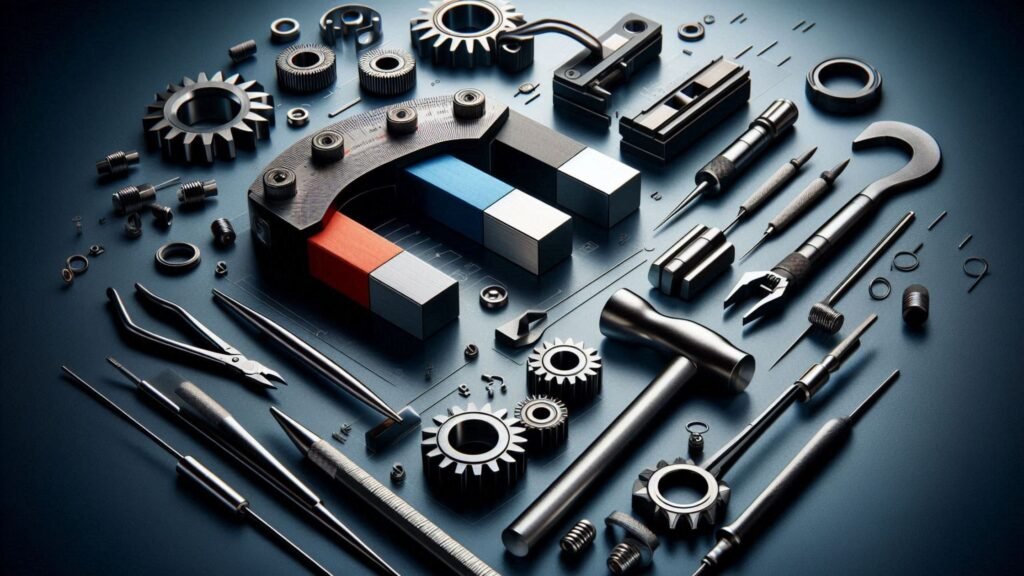

The exceptional ability of magnetic tools to increase efficiency and accuracy has made them important in the field of precision engineering. Precision components are secured, manipulated, and measured with this specialist apparatus by using magnetic forces. Engineers may greatly improve processes and results by being aware of the many uses and advantages of magnetic tools.

How Magnetic Clamps Can Improve Precision?

Magnetic clamps are one of the most important uses of magnetic tools in precision engineering. These clamps provide a robust base for complex machining operations by using strong magnets to keep workpieces firmly in place.

Traditional mechanical clamps, which can occasionally be difficult to adjust and take a long time, are no longer necessary thanks to magnetic clamps. Magnetic clamps’ simplicity of use and speedy setup lead to shorter setup times and higher shop floor productivity.

Adaptable Magnetic Vices for Hard Tasks

Another essential piece of magnetic equipment that improves precise engineering operations is a magnetic vice. These vices securely grip intricate and asymmetrically shaped parts, enabling accurate drilling, grinding, and cutting operations.

In contrast to conventional vices that depend on mechanical clamping mechanisms, magnetic vices offer a consistent and modifiable holding force that guarantees the component stays still while in use. Tasks requiring a high degree of accuracy and stability benefit greatly from this capacity.

Magnetic bases’ function in measurement tasks

Basic mounting tools for measuring instruments, including gauge blocks, electronic measurement devices, and dial indicators, are magnetic bases.

These bases use strong magnets to attach measuring instruments to various surfaces, ensuring stability and proper orientation during measurements.Magnetic bases offer flexibility and stability, which makes them perfect for applications requiring exact alignment or repeated measurements. This helps to increase accuracy and consistency.

Accuracy in Using Magnetic Pickup Tools to Manage Small Components

For handling small or fragile components that are difficult to grasp with conventional methods, magnetic pickup instruments are indispensable.

These instruments use magnetic forces to lift and move small pieces, which is very helpful when working with complex components or during assembly procedures.

Exact control over the positioning and motion of minor components lowers the possibility of damage or misalignment while also improving overall performance.

Boosting productivity using magnetic drilling equipment

Specialized instruments known as magnetic drilling systems use magnets to support the drill while it is in use. When drilling into metal surfaces, where a sturdy drilling platform is essential, this technology is especially helpful.

These systems’ magnetic bases guarantee that the drill stays firmly fixed to the workpiece, which lessens vibrations and enhances drilling precision.

This improved stability not only makes drilling more effective, but it also prolongs the drill bit’s life and produces holes of higher quality.

Solutions for Magnetic Workholding to Increase Stability

Magnetic workholding devices offer a variety of alternatives for anchoring components during machining, in addition to clamps and vices. Among these options are magnetic tables and fixtures with adjustable parts to suit different workpiece shapes and sizes.

Engineers can carry out a variety of machining processes with more accuracy and less chance of movement or misalignment thanks to magnetic workholding solutions, which provide a steady and customizable platform.

Maintenance and Durability Factors

The longevity and efficacy of magnetic instruments are significantly influenced by aspects such as maintenance and durability.

Superior magnetic tools are made to endure the rigors of long-term magnetic strength maintenance while handling the demands of precision engineering work.

Frequent upkeep, such as cleaning and examining the magnetic surfaces, guarantees peak performance and averts any problems like contamination or loss of magnetism.

Best Practices and Safety When Using Magnetic Tools

Following best practices and safety regulations when utilizing magnetic tools is crucial to protecting the equipment’s integrity as well as the user’s safety.

Effective utilization of magnetic tools is encouraged, and dangers are reduced by receiving the right training on their use as well as by adhering to installation and operation guidelines provided by the manufacturer.

Furthermore, using a magnetic pickup tool correctly for its intended purpose requires knowledge of its unique applications and limits.

The Magnetic Tool Technology of the Future

Future developments and advancements in magnetic tools for precise engineering are probably in store as technology progresses.

Advancements in magnetic materials and technology have the potential to produce magnetic tools that are even more robust and adaptable, thus expanding their uses.

It is possible to gain a competitive edge and improve accuracy and efficiency in engineering operations by keeping up with these developments and implementing new technology into engineering procedures.

Conclusion

Read Also: Gyro Compass the Best Choice for Accurate Navigation

Leveraging Magnetic Tool Benefits in Precision Engineering

In the field of precision engineering, magnetic tools have proven to be priceless resources, providing unmatched advantages in terms of accuracy, efficiency, and versatility.

Engineers can increase efficiency and precision in their work by utilizing the features of magnetic clamps, bases, vices, and other instruments. Precision engineering excellence will depend on adopting the benefits of magnetic tools and keeping up with technological developments if it is to continue evolving.

More Stories

PCD Pharma Franchise Company in Rajasthan – Oasis Bio Bloom

Adult Therapy Minneapolis: Tailored Mental Health Solutions for Adults

Roman Empire Clothing: The Influence of Ancient Styles on Christian Fashion