Production process optimisation, product quality assurance, and operational efficiency are all greatly enhanced by Manufacturing Execution Systems (MES). One of the best options available in this field is AVEVA MES, a strong instrument that enables producers to satisfy the requirements of contemporary production settings.

1. Comprehensive Production Management

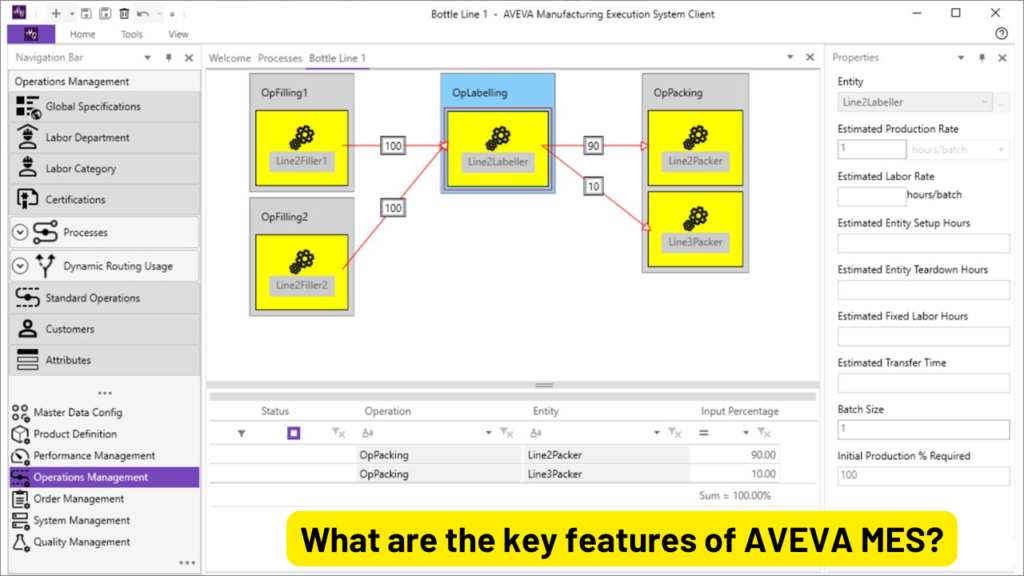

AVEVA MES’s end-to-end production management solution enables manufacturers to efficiently plan, execute, manage, and oversee their production processes in real-time.

From the receipt of raw materials to the delivery of the final product, this all-encompassing management capacity guarantees that all production operations are in line with company objectives.

Work order management, scheduling, resource allocation, and production activity tracking are some of the primary features.

Manufacturers can optimise their processes, save waste, and boost overall productivity with the help of AVEVA MES, which offers a comprehensive perspective of production.

2. Quality Management

Quality is paramount in manufacturing, and AVEVA Manufacturing Execution Systems (MES) excels in this area by providing robust quality management tools. The system allows for real-time quality monitoring, ensuring that products meet the required specifications throughout the production process. It supports in-line quality checks, Statistical Process Control (SPC), and automatic data collection from production equipment.

By identifying and addressing quality issues as they arise, AVEVA MES helps manufacturers maintain high standards, reduce rework and scrap, and ensure customer satisfaction.

3. Traceability and Genealogy

AVEVA MES offers extensive traceability and genealogy capabilities for sectors like food and beverage, pharmaceuticals, and automotive where traceability is essential.

During the production process, the system keeps track of the location, history, and movement of goods and supplies.

This entails keeping track of components, completed items, and raw materials in addition to documenting process variables and quality information.

Manufacturers may ensure that they comply with regulations and uphold consumer trust by promptly identifying and addressing concerns, such as product recalls or compliance audits, with the use of this information.

4. Performance Management

AVEVA MES provides manufacturers with robust performance management solutions to track and enhance the effectiveness of their production processes.

The system provides real-time visibility of key performance indicators (KPIs) such as production yield, downtime, and overall equipment effectiveness.

Manufacturers can find areas for improvement, inefficiencies, and bottlenecks by analysing this data. AVEVA MES’s performance management capabilities facilitate continuous improvement activities, resulting in enhanced competitiveness, reduced operating costs, and improved productivity.

5. Inventory and Material Management

Securing efficient inventory and material management is crucial to the smooth operation of industrial operations.

AVEVA MES offers advanced inventory management tools that enable manufacturers to monitor and control inventory levels in real-time.

In order to guarantee that the appropriate resources are accessible when needed, the system offers insight into raw materials, work-in-progress (WIP), and final items.

AVEVA MES assists producers in minimising waste, improving cash flow, and lowering carrying costs by optimising inventory levels and cutting superfluous stock.

6. Regulatory Compliance and Reporting

Manufacturers must prioritise adhering to industry standards and regulations, particularly in regulated sectors like aircraft, food & beverage, and pharmaceuticals. AVEVA MES offers comprehensive reporting and documentation capabilities to manufacturers, assisting them in maintaining compliance. Production data, including quality records, process specifications, and traceability data, is automatically collected and stored by the system.

7. Workforce Management

The performance of a manufacturing operation’s staff has a substantial impact on its efficiency and productivity. Manufacturers may optimise labour resources with the aid of AVEVA MES’s workforce management capabilities. The system monitors worker performance, schedules and assigns jobs to operators, and ensures the availability of necessary skills when needed. AVEVA MES helps manufacturers maintain production objectives, minimise downtime, and increase labour efficiency by giving real-time visibility into staff actions.

8. Flexibility and Scalability

Manufacturing environments are dynamic, and the ability to adapt to changing conditions is crucial. AVEVA MES is designed to be flexible and scalable, allowing manufacturers to easily adjust their production processes in response to changes in demand, product mix, or production volumes.

The system can be customized to suit diverse industries’ requirements and can be scaled from a single production line to a multi-site operation.

This flexibility ensures that AVEVA MES can grow with the business, supporting long-term sustainability and competitiveness.

9. Integration with Other Systems

Seamless integration with other systems is crucial in the networked production world of today. AVEVA MES is engineered to interface with an extensive array of corporate systems, such as Supply Chain Management (SCM), Product Lifecycle Management (PLM), and corporate Resource Planning (ERP) systems. Through seamless data flow between systems, this integration permits complete visibility and control over the manufacturing process. AVEVA MES facilitates real-time decision-making and dismantles data silos to increase operational efficiency and agility for manufacturing.

10. Analytics and Reporting

Data-driven decision-making is a cornerstone of modern manufacturing, and AVEVA MES provides powerful analytics and reporting tools to support this. The system collects and analyzes production data in real time, providing actionable insights that help manufacturers optimize their operations.

By leveraging the power of analytics, AVEVA MES empowers manufacturers to make informed decisions that drive continuous improvement and operational excellence.

AVEVA MES is a comprehensive and powerful solution that offers a wide range of features designed to optimize manufacturing operations. From production management and quality control to traceability, performance management, and regulatory compliance, AVEVA MES provides the tools manufacturers need to achieve operational excellence. Its flexibility, scalability, and integration capabilities make it a valuable asset for manufacturers looking to stay competitive in today’s fast-paced and ever-evolving market. By leveraging the key features of AVEVA MES, manufacturers can improve efficiency, reduce costs, and deliver high-quality products that meet customer expectations.

Visit Also :- How to Get the Perfect light Brown Nails Color Backstageviral.com

More Stories

Autonomous Mini Tractors:?Do These Game Changers Work?

Dental Billing Software: How It Can Boost Your Income

Transforming Retail Experiences with AI in Retail: Personalization, Automation, and Smarter Inventory Management